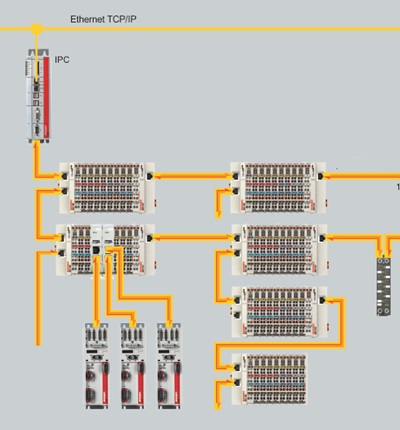

PLC network diagram

Article#: 00086

Date: 2024-02-08

Author: Radim

What is a PLC network diagram and what is it good for?

A PLC network diagram is a visual representation of the entire automation system, encompassing PLCs, input/output modules, communication networks, devices, and power supplies.

It serves as a high-level visualization tool that depicts the architecture and connectivity of an industrial automation system.

It provides on a single sheet a comprehensive overview of how components are interconnected and communicate within the system, offering numerous benefits for stakeholders involved in the automation process.

PLC network diagrams are invaluable for:

1. Visualization: Providing a visual representation of the entire automation system, including PLCs, I/O modules, communication networks, and other devices.

2. System design: Assisting engineers in planning the layout of components and communication pathways within the automation system.

3. Troubleshooting: Aiding technicians in identifying and diagnosing issues within the system, leading to faster resolution and reduced downtime.

4. Maintenance: Guiding maintenance personnel in performing routine maintenance tasks and updates on system components.

5. Documentation: Serving as a comprehensive reference for documenting system architecture, configurations, and revisions.

6. Communication: Facilitating collaboration and communication among people involved in the design, implementation, and maintenance of the automation system.

How should a useful PLC network diagram look?

A useful PLC network diagram should incorporate several key elements to ensure clarity, comprehensiveness, and effectiveness:

1. Component representation: Include icons or images representing PLCs, I/O modules, devices, and other components within the automation system.

2. Component names and labels: Clearly label each component with its name, identifier, or function to aid understanding and identification.

3. IP addresses and node numbers: Include IP addresses for devices on Ethernet-based networks and node numbers for devices on other communication protocols.

This information helps in configuring, identifying, and troubleshooting devices within the network.

4. Power supplies: Show individual power supplies and their connections to components within the system.

5. Connection pathways: Illustrate communication pathways between components, including wired and wireless connections.

6. Communication networks: Depict communication networks such as Ethernet, Profibus, Modbus, etc., and show connections between components and network devices.

7. Color notation: Use color coding to differentiate between different types of bus cables or communication networks, enhancing visual clarity and comprehension.

8. Legend or key: Include a legend or key within the diagram to explain the meaning of symbols, colors, IP addresses, node numbers, and labels used.

9. Consistency and accuracy: Maintain consistency in notation, labeling, and representation throughout the diagram to ensure clarity and accuracy.

© Radim-Automation, 2020–2025. All rights reserved.

Sharing of this article is permitted with proper attribution (link to the original page).

Related previous articles:

- Diagnostic tools

- Event logger as the very first function implemented in the program

- It doesn't work without sensors

- Clear signals

- Design considerations for effective HMIS

- Safety relays versus safety PLC

- Documentation issues

- Visual modeling

- Machine modularization

- Abbreviations

- Modular software architecture

- Hardware concept

- A good concept = Complete set of suitable solutions

- Are there also any disadvantages?

- Design machines with a focus on user's abilities and needs

- More than just start and stop

- Safety first!

- Introduce the terminology and standardize it!

- Industrial evolution - Listen to your customers and follow new trends!

- Have an expert on hand!

- Focus on target!

- Think on paper!

- Sharpen your axe before you start felling!

- Keep it simple!

- Transparency and reliability

- From an idea to a consistent system

Related next articles:

- Keep the documentation up to date throughout the project

- Dream of a platform-independent PLC program

- Keep everything you need together

- Hidden dangers during commissioning